Why Used Air Compressors Are a Smart Choice for Cost-Conscious Businesses

Introduction

For many industrial and commercial operations, compressed air is a non-negotiable utility. It powers tools, machinery, and production processes across manufacturing, automotive, food processing, and more. However, purchasing brand-new equipment is not always the most practical or cost-effective option—especially for growing businesses or those looking to expand capacity quickly. This is where used air compressors come into their own, offering reliable performance at a significantly lower investment when chosen wisely.

Understanding the Value of Used Air Compressors

More Than Just a Budget Option

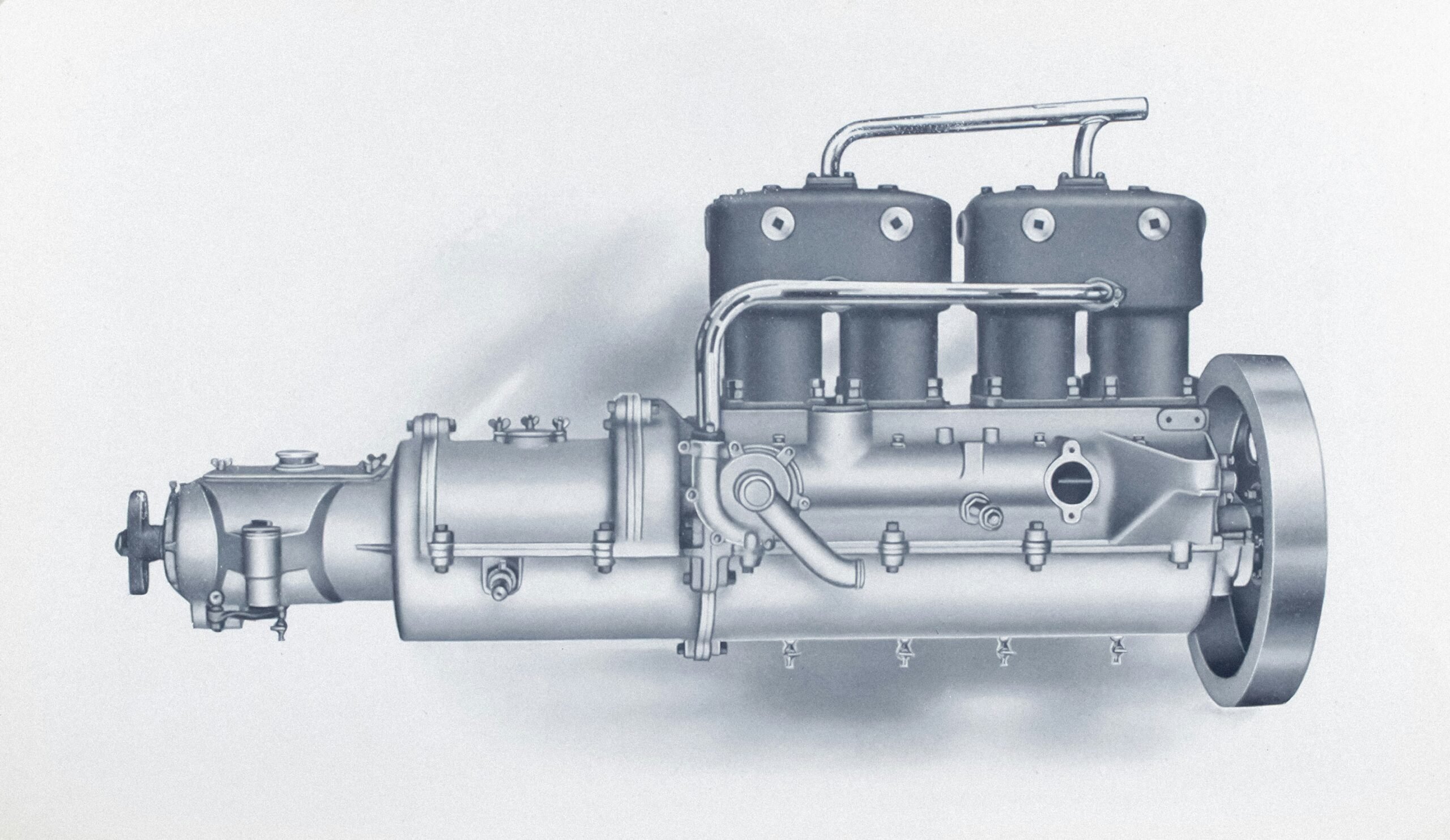

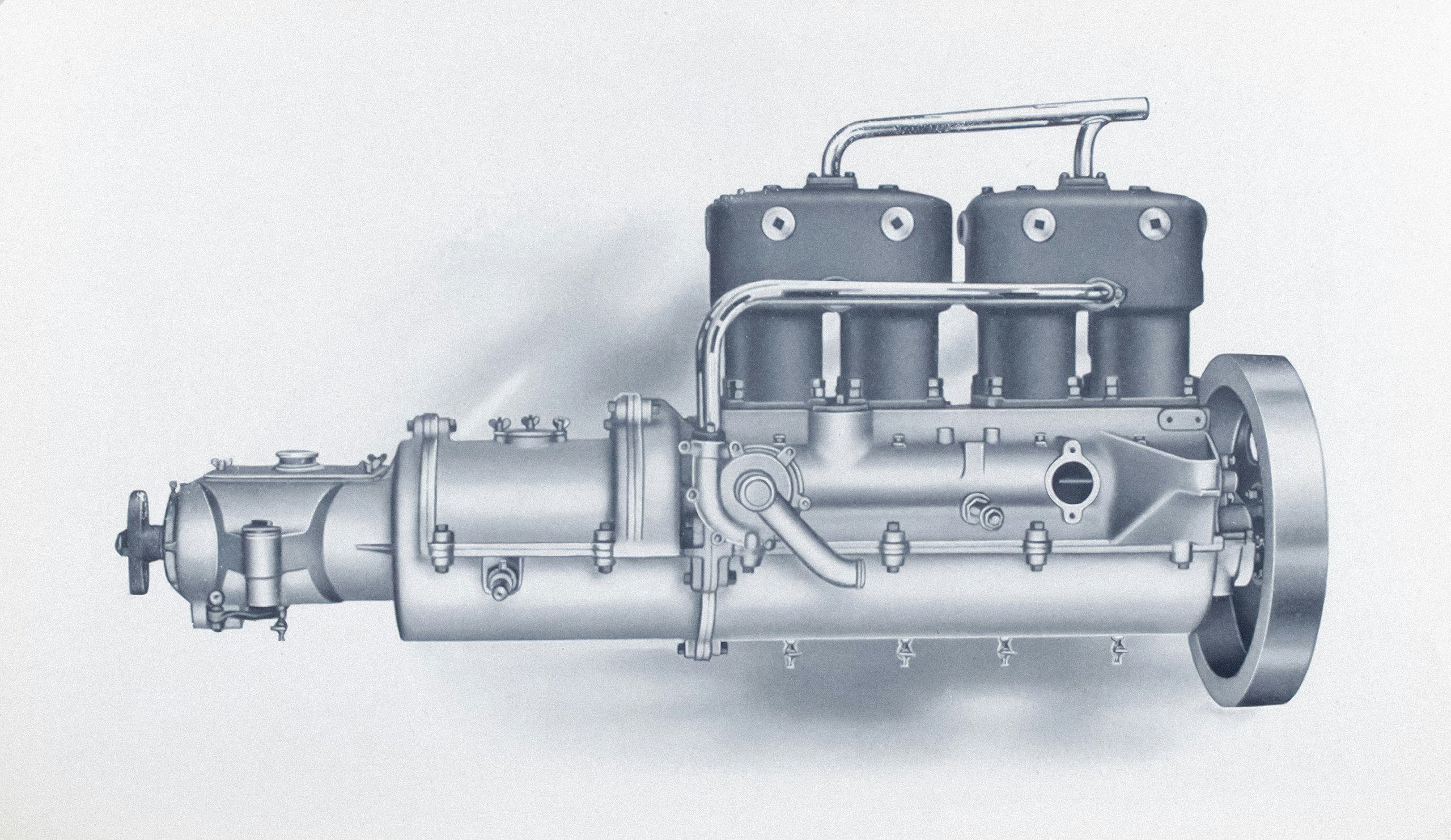

There is a common misconception that used equipment is inherently unreliable. In reality, many air compressors are built for long service lives, often operating effectively for decades when properly maintained. A professionally inspected and serviced used compressor can deliver performance comparable to a new model at a fraction of the cost.

High-quality used air compressors are typically sourced from well-maintained installations, refurbished where necessary, and tested to ensure dependable operation. This makes them a practical option rather than a compromise.

Ideal for a Range of Applications

Used compressors are well suited to:

- Businesses starting up or scaling operations

- Temporary or short-term projects

- Backup or standby air supply

- Replacing ageing equipment without major capital outlay

In many cases, a used unit provides exactly the level of performance required without overinvesting in unnecessary capacity.

Key Benefits of Choosing Used Air Compressors

Significant Cost Savings

The most obvious advantage is cost. Used compressors can be substantially cheaper than new equivalents, freeing up capital for other areas of the business such as staffing, tooling, or energy-efficiency improvements.

Lower upfront costs also reduce financial risk, particularly for smaller businesses or those operating in uncertain markets.

Faster Availability

New compressors often come with lead times for manufacturing and delivery. Used units, by contrast, are typically available immediately. This can be crucial when equipment fails unexpectedly or when production needs to increase quickly.

Proven Reliability

Unlike brand-new equipment, used compressors have a known operating history. When sourced from reputable suppliers, they are inspected, serviced, and tested before resale. This process helps identify and resolve potential issues before the compressor is installed at your site.

What to Look for When Buying a Used Air Compressor

Service History and Refurbishment

A reliable supplier should be able to provide details of servicing, repairs, and any refurbishment work carried out. Components such as motors, airends, and control systems should be checked thoroughly.

Replaced consumables—filters, seals, and belts—are a good indicator that the compressor has been prepared for continued use rather than sold “as seen”.

Matching the Compressor to Your Needs

As with any compressed air purchase, selecting the right specification is critical. Consider:

- Required airflow and pressure

- Duty cycle and operating hours

- Available space and power supply

- Air quality requirements

Buying a used compressor that is poorly matched to demand can lead to inefficiency and higher running costs, offsetting the initial savings.

Warranty and After-Sales Support

Many reputable suppliers offer warranties on used equipment, providing peace of mind and protection against unexpected faults. Access to ongoing servicing and spare parts is equally important for maintaining performance over time.

Sustainability and Environmental Benefits

Extending Equipment Lifespan

Choosing used equipment supports a more circular approach to industry. By extending the working life of existing compressors, businesses reduce demand for new manufacturing, conserving raw materials and energy.

Lower Carbon Footprint

Manufacturing new industrial equipment has a significant environmental impact. Opting for a refurbished compressor can help reduce your overall carbon footprint while still meeting operational needs.

Practical Example: Real-World Savings

A small engineering firm required additional compressed air capacity to support a new production line but had limited capital available. By selecting a refurbished rotary screw compressor rather than a new unit, the business reduced upfront costs by over 40%. The compressor met performance requirements, integrated seamlessly with existing pipework, and allowed the company to invest remaining funds in energy-efficient lighting and tooling.

Frequently Asked Questions

Are used air compressors reliable?

Yes, when purchased from a reputable supplier. Professionally inspected and serviced units can offer many years of reliable operation.

Do used compressors come with a warranty?

Many suppliers provide warranties on used equipment, although terms may vary depending on age and condition.

Can used compressors be energy efficient?

Absolutely. Many used models feature modern designs and efficient motors. Proper sizing and maintenance are key to keeping running costs low.

Is it possible to upgrade or modify a used compressor?

In many cases, yes. Controls, dryers, and monitoring systems can often be added or upgraded to suit operational needs.

Who should consider buying used air compressors?

Used compressors are ideal for SMEs, expanding businesses, temporary installations, and companies looking for cost-effective backup systems.

Conclusion

Used air compressors offer a compelling balance of performance, value, and sustainability. When sourced from trusted suppliers and matched carefully to operational requirements, they provide a reliable compressed air solution without the high capital costs of new equipment. For businesses seeking flexibility, fast availability, and smarter use of resources, investing in used air compressors is not just an economical decision—it is a strategic one.