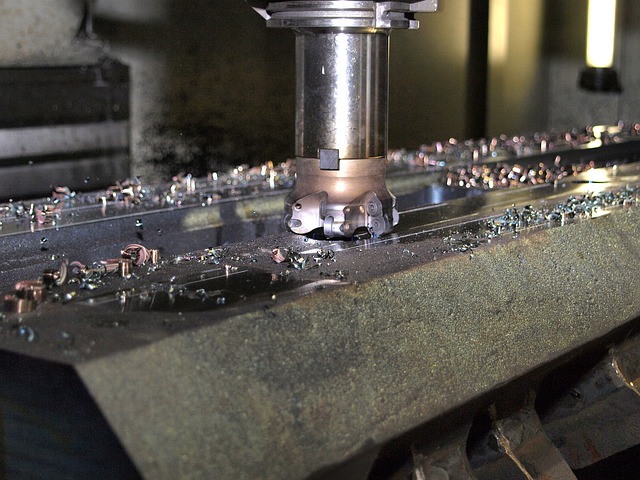

How CNC Engineering Services Accelerate Product Development and Prototyping

In today’s world of competition, speed of product development and prototyping cannot be overemphasized—when it comes to competing in the marketplace. Thus, CNC engineering is in great demand—to provide the necessary product idea realization, in a fast, accurate, and efficient way.

CNC technology, for instance, makes it easy for a business to produce high-quality prototypes within a very short time, due to automation of complicated machining activities. This capability is useful to speed up development cycles while ensuring that testing procedures are consistent and accurate.

Here are the key ways CNC engineering services promote advancements in product development, including precision, speed, flexibility, and cost.

Accuracy and Uniformity in Prototyping

Among the major benefits of CNC engineering, one can mention accuracy and precision in the process of creating prototypes. CNC machines perform cutting and drilling operations at a precise level. Furthermore, specialization in CAD/CAM technology leads to the reduction of several factors associated with manual control of CNC engineering services. This makes it easy to attain a high degree of sameness for successive versions of a prototype, which is essential for stability and reliability.

Reduced Lead Times for Faster Market Entry

One key consideration during the PD process is the time-to-market. CNC engineering services greatly minimize the time it takes to transition from a mere idea to a prototype. Thanks to the application of CAD/CAM technology, CNC services offer reduced lead times, which means that a company can proceed to the next phase without delay. For instance, as soon as you prepare a design file the CNC machines can proceed. THus, you can generate prototypes in the shortest time possible. All without having to spend a lot of time readjusting settings and equipment.

In industries such as electronics, automotive, and aerospace, frequent shifts in designs, and rapid development of high-quality prototypes are a key driver of competitiveness.

Enhanced Design Flexibility and Customization

The other benefit of CNC engineering services is versatility when it comes to design. CNC machines are versatile and can use metals, plastics, and other materials such as composites. It is this flexibility of technology that affords the freedom of designers and engineers. After all, it allows them to play around with various types of materials and create shapes that would otherwise be very difficult to make through conventional methods of manufacturing.

This flexibility helps to advance the development of prototypes and to customize the final product, which is beneficial for a company.

Cost-Efficiency in the Development Process

Outsourcing CNC engineering services may cost a few extra dollars upfront, however, the real benefits rack up in the later stages of the product development cycle. Numerically controlled machining reduces scrap costs. This is because of the accuracy of the tool paths and the little chance of mistakes. These efficiencies are of immense benefit to companies who are using costly materials.

In addition, CNC machines can work unlimited hours with less human interaction. Through this, CNC engineering services can reduce the cost of prototyping and product development. Thereby, allowing firms to perhaps spend more on research or in other key sectors of their business.

Improved Scalability for Transition to Production

CNC engineering services also come in handy in terms of scalability. This is very critical as you transition from prototyping to mass production. When the design is set, the same CNC programs used in the prototyping process can be used in production. Thus, eliminating differences between the prototypes and the final products. This simplicity frees you from the cumbersome rearrangements of machines and the formation of new procedures for production. Both of which are time-consuming and resource-intensive.

Conclusion

Conventional machining has been overtaken by CNC engineering services in product development and prototyping. This is because they deliver accuracy, efficiency, and versatility that cannot be achieved through traditional machining. Utilizing CNC engineering services offers firms a competitive advantage. Especially as it ensures both time-to-market acceleration and improvement of products’ quality, while decreasing the costs of product development.