Is CNC Business Profitable?

Making a profit when you start a CNC-based manufacturing business will clearly be a top priority, but if you are a newcomer to this area you may not know how quickly this can be achieved, or how easy it is to do. In a manufacturing tech business, a key question before diving in is, “Is CNC business profitable?”

To clear up any uncertainty, here is a look at the expectations you should have for profitability if you build your business around a CNC machine.

Assessing the market

The first thing to note is that almost any business can be profitable, so long as you do your research and take the right steps from day one.

In the context of creating a CNC business, the first thing to think about is the kinds of demands for associated services that exist at the moment but which are either unfulfilled or offer room for maneuver.

Scrutinizing the market in this way will provide you with a template on which to base your business plan, as well as letting you work out the kind of equipment you should invest in, whether that might be engine lathes, milling machines or other modern kit.

Calculating staff costs

The other barrier to profitability will be how much you need to pay employees to operate the machinery and handle other aspects of the organization, especially in its early stages.

If you are planning to do most of the work yourself, running a one-person workshop for small scale CNC jobs, then this will be less of an issue. If you are intending to recruit experienced CNC machinists with the right skills to use the equipment instead, then this will need to be factored into your calculations.

Wrangling staffing costs can be something of a balancing act, and you need to be prepared to spend money to make money. For example, if you win a significant contract or net a lucrative order from a big client, but you lack the people power to fulfill it efficiently, you could regret the failure to expand your workforce sooner rather than later. Once again the volume of demand in the market may dictate your decisions here.

Making the most of marketing

You could have the best equipment and the most talented team members in the country, but unless you are prepared to market your CNC business then you will have a tough time turning a profit.

Even if there is relatively little competition in your area, you will still need to promote your new firm effectively to win over customers and establish your brand. Using a mixture of traditional marketing options and modern, digital solutions will be sensible.

If the market is very competitive, then courting customers elsewhere by maximizing the impact of your online presence is another important step. This could also stimulate significant growth, so long as you manage it effectively.

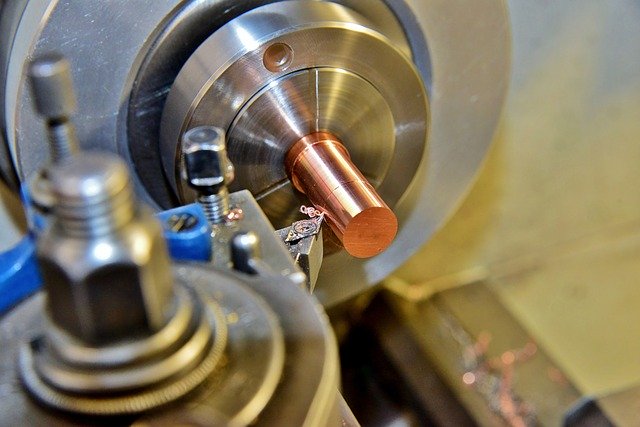

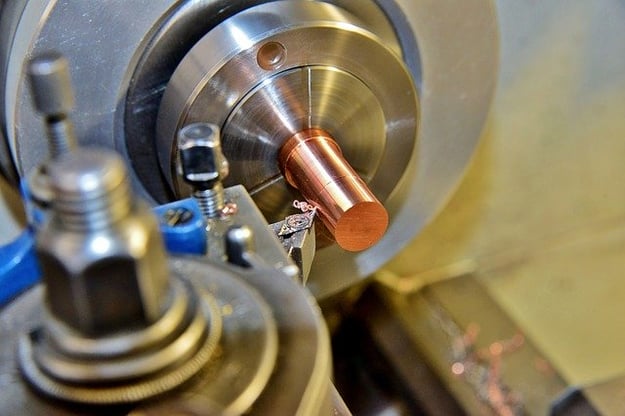

Ensuring excellent quality

Creating high quality products from tip top materials will be necessary for any small, ambitious CNC business that wants to generate healthy profits. As such, quality control is vital and something which should be considered at every point of the production process.

While you should obviously endeavor to impress clients with the parts you provide, you also need to consider that even if you put all of your efforts into manufacturing components precisely, this could be for naught if the underlying materials are not up to scratch. To make a profit, it is important to take QA into account during procurement, as well as once manufacturing is underway. This is key to answering that question, “Is CNC business profitable?” in a positive way.

Finally, remember that almost no business is an overnight success, so be patient, work hard and the profits should come to you eventually.