3 Steps to Finding the Best Rubber Seal for Your Application

The choice of rubber seals for your company’s applications is very important. Though small and seemingly insignificant, rubber seals play an integral role in many manufacturing industries, including the medical, aerospace, food, and automotive spaces.

Choosing the wrong type of rubber seal can reduce your equipment’s efficiency and lead to serious problems such as loss of fluids, delays in the supply chain, and faulty products. To avoid this, manufacturers rely on different types of rubber seals and gaskets in equipment to ensure smooth manufacturing. These seals work by locking in liquids and gases and preventing external elements from disrupting the flow of an application.

Rubber seals have a wide variety of uses across many different industries and though they look alike, they differ in designs, materials, and other specifications. Thus, several factors must be kept in mind while designing or ordering the seals for your industrial applications.

Here are some of the best ways to find rubber seals that meet your applications.

1. Define the Task

Rubber seals do not all have the same purpose and tolerance. Defining the task for which the seal will be for will aid you in your choice of an effective seal. For example, seals for medical devices have exposure to various chemicals and need sterilization. However, seals for aerospace or car manufacturing need to endure high temperatures and wide ranges of pressure. Therefore, it’s crucial to note the environment of use before settling on a specific type of seal. Some of the factors that should be taken into account are:

- Resistance needs (temperature, pressure, water, chemical, weather)

- Friction level

- Chemical compatibility

- The total amount of load

- Closing force necessary

- Toxicity level

Find out if the seals can be sterilized, if they can come in contact with other materials, and generally whether they can function in the situation you plan to use them.

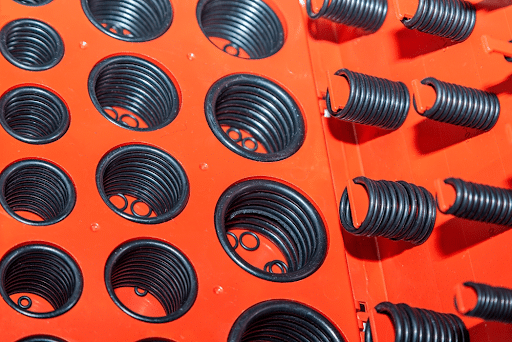

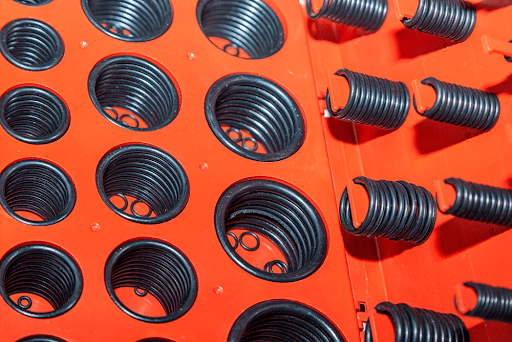

2. Determine the Appropriate Material and Dimensions

Rubber seals are made from different materials that have different properties. The size of the seal also matters in order to achieve adequate sealing. If the cross-section is too small or too large, the seal may not compress properly or it may disrupt the connection between the two surfaces. The most common materials rubber seals are made from are:

- Silicone. This is popular for the manufacture of pharmaceuticals, medical devices, cosmetics, and food. It can withstand a wide range of temperatures, has low toxicity and is highly biocompatible and resistant to chemicals.

- Nitrile rubber. Budget-friendly choice for o-rings and seals that are in contact with oil. Mostly for the oil and gas industry.

- ManniGlas and FiberFrax. For use in conditions of extremely high temperatures

- EPDM (ethylene propylene diene monomer). Suitable for the auto industry in braking and cooling systems. Cost-effective and can withstand outdoor use.

- Virgin Teflon. Suitable for very low temperatures. This is applicable for use in MRI machines and space equipment.

- Fluorocarbon (Viton), Flexible PVC and Chloroprene or Neoprene

If you’re looking for a seal for medical, cosmetic, or food applications, then look into the impurities of the sealing material. This is important as they can leak and cause contamination. Therefore, in highly regulated industries, sealing material mustn’t contain toxic or potentially carcinogenic impurities.

3. Choose Your Source

If your business relies on rubber seals, it might be overwhelming to pick a suitable option for an application from the variety of options. It is ideal that you partner with a reputable manufacturer and supplier on whom you can rely.

When choosing a rubber seal manufacturer, ensure that they have a good reputation, a large and varied inventory of seal types, and specialized services like custom/bulk orders. Make sure you don’t have any disruptions and that they support your supply chain. Most of all, choose someone whose expertise you could rely on. The rubber seal manufacturer should advise you on the choice of material based on the factors surrounding your usage, while also taking into consideration required regulations and certifications.

Making the Right Choice in Rubber Seals

When it comes down to it, there is no single type of rubber seal that is suitable to do everything. Therefore, you can’t just call up a manufacturer and ask for a random seal type. You need to absolutely define your application, and understand the conditions the seal will be under and the task it is to perform. Then, get in touch with a manufacturer to find the material and seal type that fits.